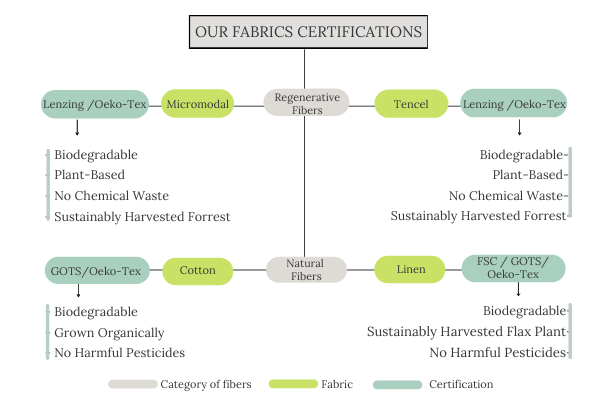

GREEN FABRICS

Fabric selection plays a large part in both comfort and sustainability, which is why we choose to work with some of the softest, most environmentally friendly fabrics on the market.

All of our fabrics are plant-based and naturally processed or recycled.

Why process naturally?

Air, water, and earth give trees life. Lenzing uses these natural raw materials for the production of TENCEL® and Lenzing Modal®, allowing nature to return to nature at the end of a product’s life.Starting from our raw materials, we make sure the trees used for the production of our staple Modal fabric come from reliable forests and not deforestation. We work with Lenzing Modal and OEKO Tex certification to provide that safety and assurance.

OUR FABRICS

Lenzing™ Modal

Known for its incredibly soft texture, we use locally sourced Lenzing™ Modal for our knit and jersey garments. This plant-based fiber is sourced from beech trees in responsibly managed forests, making it both renewable and biodegradable.

Manufactured in a closed-loop process, 95% of the chemicals are captured and reused, dramatically reducing waste.

We conducted a personal experiment to verify the biodegradable fact of MicroModal. To our incredible surprise, it fully reverted back to Nature in only 7 weeks. Check our video on IG.

Micromodal is our DNA fabric, it is finely knit and has a soft and silky feel, inspiring soft, flowing designs that drape beautifully on the body. It is a luxurious plant-based and regenerative fiber known for its exceptional softness and comfort, breathability and the garment made will always get back to its shape even if it is a supple and stretchable material. It’s lightweight and resists wrinkling (which makes it fantastic for travel) and holds its color after repeated washing and wearing.

Its fiber limits the proliferation of odors and bacteria, it does not retain water and therefore dries much faster than other fabrics. This semi-synthetic fiber is made from the pulp of beech trees. Beech trees are self-seeding plants and renewable resources. Our micro modal is certified from “LENZING™ to ensure the trees used in our fabric production are sustainably harvested and are not sourced from ancient and endangered forests.

Label and certify modal production is at the heart of our concern because every year forests of the size of Greece are taken down to be used in the process on non responsible or unethical wood factories used. This forest degradation contributes to the annual disappearance of thousands of animal and plant species. We are requiring labeled fabric also to make sure that not harvested, no civil rights of the people have been violated.

“Leading in sustainable sourcing with a decade-long clean record

Wood and pulp are the most important raw materials for Lenzing’s sustainable production of cellulosic fibers. The Lenzing Group is particularly proud of its decade-long clean record of sustainable wood sourcing, evidenced by its long-standing credible commitment to wood certification, which Lenzing pioneered already in the 1990s. Lenzing’s commercial wood sources are 100 percent either certified by FSC®[1] or PEFC™[2] or controlled in line with FSC® standards. In addition, Lenzing has completed the second Canopy verification audit.”

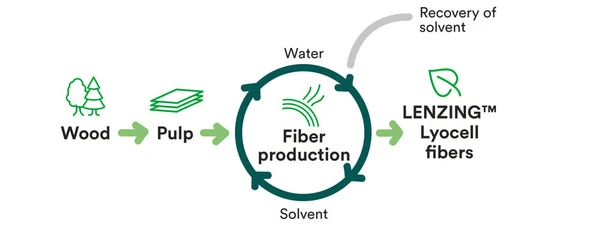

100% TENCEL™

For our woven garments, like several of our pants and jackets, we use TENCEL™.

This plant-based material is the trademarked version of Lyocell.

It’s certified sustainable and is produced from eucalyptus trees and non-toxic solvent. The non-toxic solvent used to transform the fiber into fabric is recovered at 99.7% making it one of the most recyclable and reusable materials. It has a low environmental impact because it is produced in a quasi-closed loop circuit where the materials are constantly recycled, purified, and reused. The TENCEL™ is a breathable, resistant fabric, its nickname is “vegetable silk”, due to its similarity to silk.

Organic Cotton / TENCEL™ Blend

We use a blend of Organic Cotton and TENCEL™ for our trench coat and shorts. This particular blend is made from Japanese deadstock fabrics from Zen Textiles.

Organic cotton

Lâcher Prise Apparel wishes to work more with linen and organic Cotton uses. Organic cotton represents 15% of the fibers we are currently using for our clothes manufacturing.

Why is organic cotton better than regular cotton for us and the environment?The process used during the fabric of organic cotton consumes 87% less water than conventionally grown cotton and emits 45% less gas emissions. The process generates way lower greenhouse gas and energy compared to conventional cotton. Also, its fiber is bleached with hydrogen peroxide and not with chlorine, and the dyes are made without carcinogenic substances.

Biodiversity is enhanced due to diversified cultivation and non-use of GMOs. His production is more durable for the environment and is less chemical for the workers. “Worldwide, every year more than 1 million farmworkers have been hospitalized due to the use of chemicals in the non-organic cotton process.” Organics label farms offer as well fair wages and better conditions for their workers.

Global Organic Textile Standard (Gots) COTTON

At Lâcher Prise, we choose to work with the GOTS label, which is the world leader in certification for organic textiles.This certification covers processing, manufacturing, packaging, labeling, trade, and the distribution of all textiles made from at least 70% certified organic natural fibers. This label is defined by a high level of environmental criteria all along the supply chain of organic textiles and also requires compliance with social criteria. It is for all this reason that Lâcher Prise is eager to use more Organic cotton in their future collections.What is Deadstock Fabric?

Can you believe that only 10% of mass-produced fabric rolls will be used during production? Those mounds of deadstock fabric can end up in landfills, or they can be used to create beautiful new garments with a long life.

We want to do our part to lower that statistic by not overproducing clothes and materials. We source a lot of our materials from local mills and ethical manufacturers. By using their leftover deadstock, we eliminate the need to spin new fibers, reducing landfill waste and the impact on our forests.

Why are we interested in working with Natural Dye?

Lâcher Prise is always looking for ways to improve its impact on our environment. In order to correct our Water & Chemicals score currently at 85%, we are slowly moving toward a natural dye process.

Natural dyes are a renewable source of coloring materials. Natural dyes are derived from plants, animals, or minerals. Biological sources such as vegetables, plants, insects and fungi provide the majority of natural dye production. The process contains no harmful chemicals nor carcinogenic components, common to artificial or synthetic dyes.

GREEN MATTERS

We have recently started working with Green Matters; a company of natural dye located in Lancaster, Pennsylvania, to develop beautiful and natural colors for our upcoming Spring/Summer 2022 collection . Their ethos is to “manufacture needs of fashion brands without damaging the environment”.

How are they making it possible?

-They use plant-based dyes, natural fabrics, sustainable production, low air miles, and local manufacturing.

-They use Lancaster agricultural HUB waste to make the color dye.

-They exploit rainwater; gathering over 60,000-gallon in a cistern underneath their studio to be used in production, using the existing resources of our planet.

The best part is both the dye mordants and organic plant matter are completely compostable. And also, using rainwater allowed Green Matter to remove naturally the water impurities that are impacting the dying result.

This collaboration will provide Lâcher Prise with an additional value to their environmental impact, but also drain down the water use on the creation cycle of our garment. We aim by the end of 2022, to have reached a 100% for our Water & Chemical Index.